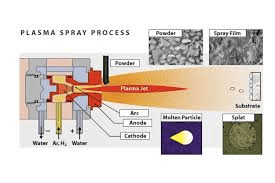

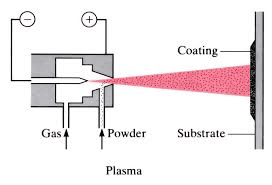

Using Plasma Spray or plasma spraying is a way in which heated plasma molecules can be directed onto the surface of an object to provide it with an outer coating. The chosen powdery substance is added to a plasma flame and then heated and powered at a high velocity towards the surface of the object through a spray gun.

Now let’s get a little bit more technical.

The spray gun is prepared (it is made from a tungsten cathode and a copper anode), the plasma gas, which itself is made up of a mixture of nitrogen, helium, argon and hydrogen, moves up through the tungsten cathode and then through the nozzle shape of the anode. This then produces the high voltage that is needed in order to expel the molecules towards the surface.

The powdered particles are added to the hot plasma where they melt. This allows them to be projected over longer distances.

Plasma spraying can be used on a variety of materials and allows for a second outer coating to be applied relatively easily and to give the original item extra benefits such as electric conductivity, resistance to extremes of temperature, resistance to corrosion and abrasion.