With more industries becoming inclined towards automation over manual work, vacuum conveying is distinguishing itself as the clearest path of progression for the industry. To illustrate why, we’ve put together this article, elucidating the benefits of vacuum over mechanical or manual.

Key Features

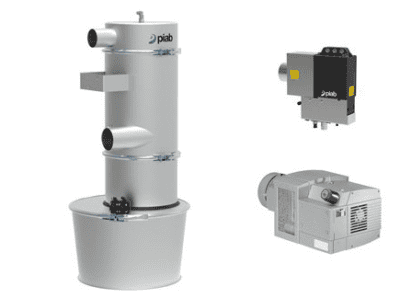

Vacuum conveying systems already seem more specialised than standard models in their design and purpose, but they can provide even more versatility.

Tailored designs and modifications that suit the working environment can be installed, for which the characteristics of the processed materials will also be factored in.

With a normal vacuum conveyor, you will find a single pickup point for material. This can be a drum or a bag-dump station, through which the desired material is initially processed.

Depending on the size of the conveyor and the material load, you can adjust specifics in the design. Heavier materials need more airflow and a stronger motor, for example, and smaller conveyors require fewer filters.

Despite these meticulous modifications, the machines remain low-maintenance, with check-ups recommended, but not required. A thorough breakdown of the machinery and processes can be found online at sites such as https://www.aptech.uk.com/pneumatic-conveying-systems/vacuum-conveying.

Types

There are two main modes of pneumatic transport. Both dilute phase and dense phase types involve the material being processed through a gas stream. Put simply, the dilute phase has a higher velocity gas stream than the dense phase, but this explanation is reductive. A detailed explanation can be found here on the aiche website.

Advantages

The vacuum conveying process is typically cheaper than standard counterparts, whilst also being more efficient, versatile, and reliable. The only drawback would be difficulty with large quantities of material, a weakness made up for by its impeccable efficiency.

A vacuum conveyor is also fairly simple to operate, with its automatic nature requiring less manual input than mechanical versions. Pneumatic models can remove solid material without disturbing the overall process, and the loading and unloading cycles are easily repeated processes.

The material also doesn’t need to be in any specific form to be transported. A vacuum conveyor can handle many types of material, performing exceptionally well with powders compared to its counterparts.