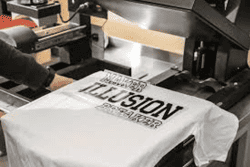

Screen printing is the reproduction of a design on a surface using an electric permanent inkjet printer. The image is printed directly onto the substrate with little to no preparation or treatment. Most commercial uses of screen printing use silk screening for their products. Screen printing was used as a commercial product since the early twentieth century and has become increasingly popular in various industries, including building signs and labels. The process is used to make a wide range of different objects, including but not limited to, T-shirts, luggage tags and even certain types of sports equipment.

In screen printing, an image is printed on a substrate in order to form a part or component. In most cases, the image is printed on a thin, semi-translucent film of material that is applied to the substrate using a special application tool that leaves a raised imprint on the substrate. This imprint is the image that will be transferred to a screen later, generally in the color or black and white portions of the image. You can buy Screen Printing Equipment to do this from companies such as Mascoprint.

The actual procedure used to create a screen is relatively simple, although some older methods use chemicals that can degrade over time, resulting in poor image quality and reduction in print speed. Modern screen printers are now made with a variety of new, durable materials that do not deteriorate and can handle high print densities for years on end. Some modern substrates include polyester and metallic ink, which both offer the best results when it comes to transferring an image. When looking at screen printing, it is important to consider the kind of paper you will be using and the thickness of the substrate. The thicker the substrate, the better quality the final product will be.